CIX100

CIX100 Inspection System: Simplify Your Technical Cleanliness

.

Capture Data in a Single Scan

An innovative polarization method based on wavelength separation and color detects both reflective (metallic) and non-reflective particles in a single scan.

Integrated into the microscope frame, this high-throughput design enables scans to be completed twice as fast as the classical method

Review Particles in Real Color

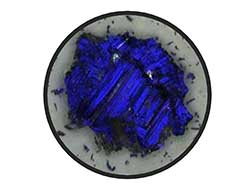

Activating real color mode enables users to view particles in their actual colors, providing additional information to identify the particle type as metallic or non-metallic.

Particle as seen by the system during detection and analysis. The blue color indicates that this particle is metallic.

The same particle as seen during the review mode in real color using the U-ANT filter and the color correction mode. The particle is confirmed as metallic.

Contaminants are automatically analyzed

sorted into size class bins defined by the selected standard and are color coded to clearly indicate which size class exceeds a predefined limit.

A statistical control chart function visually illustrates the level of particle class compliance, for improved reliability.

Predefined acceptable particle counts per size classes are displayed, and the sample can be validated (OK) or rejected (NOK) even before the complete membrane is acquired.

Detect Dark, Bright, Small, and Large Particles

Live processing and classification of both small and large particles according to international standards (2.5 µm up to 42 mm).

Image stitching automatically reconstructs images of large particles.

Scan dark particles on a bright background or vice versa.

Revise Inspection Data

Based on the stored particle position information, the stage directly repositions at a selected particle position for further investigation and revision.

Flexible for Evaluation and Revision

All particles and classification tables, overall cleanliness code, particle location, and the standard used appear in one view.

Trend Analysis

Data statistical analysis can be performed over time and graphically displayed.

Deep Data Insights for Direct Identification

Visualization of different particle view e.g., the largest reflective or non-reflective particles.

Clear arrangement of images, data and results for immediate decision making for reprocessing.

Advanced Microscopy

Microscope mode enables you to leave the dedicated cleanliness inspection workflow to perform microscopic imaging.

Expand the microscope mode capabilities with optional material analysis solutions, such as:

- Grain Intercept

- Grain Planimetric

- Cast Iron

- Inclusion Worst Field

- Layer Thickness

- Dendrite Arm Spacing

- Phase Analysis

- Porosity

- Coating Thickness