| |

Grain Sizing Planimetry

The Grain Sizing Planimetry Materials Extension contains functions for determining and documenting grain size according to the planimetric procedure. Due to integrated task automation, it is easy to define fixed task sequences for frequently recurring analysis experiments. When using a motorised stage, multiple samples can be analysed automatically. Grains size planimetry evaluates grain size distribution according to the ASTM, DIN and JIS standards. The Grain Sizing Planimetry Materials Extension also supports user-defined protocols.

|

|

|

|

Key Features |

|

|

Measurement based on: grain-boundary reconstruction Measurement based on: grain-boundary reconstruction

Grain boundaries: light, dark or etched grain surfaces Grain boundaries: light, dark or etched grain surfaces

Results: g values and statistics, sandwich-layer analysis, bimodal structural analysis, statistics on grain sizes and grain-size histograms, detailed single-grain analyses, elongation Results: g values and statistics, sandwich-layer analysis, bimodal structural analysis, statistics on grain sizes and grain-size histograms, detailed single-grain analyses, elongation

Display of results as an overlay to the image and as a spreadsheet Display of results as an overlay to the image and as a spreadsheet

Automatic creation of compliant report Automatic creation of compliant report

Standard supported: DIN 50601,JIS G 0552, ASTM E 112 Standard supported: DIN 50601,JIS G 0552, ASTM E 112

Specifications:

Description:

Analyses the grain size (Planimetry method) Description:

Analyses the grain size (Planimetry method)

Supported Standards:

ASTM E112, DIN 50601, JIS G0552 Supported Standards:

ASTM E112, DIN 50601, JIS G0552

Measurement Types :

Automatic measurement (manual definition of separator and sandwich threshold) Measurement Types :

Automatic measurement (manual definition of separator and sandwich threshold)

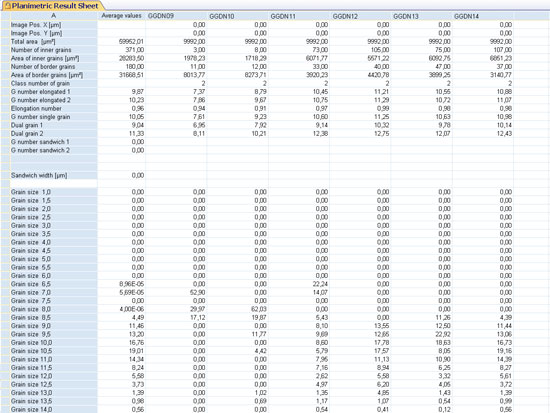

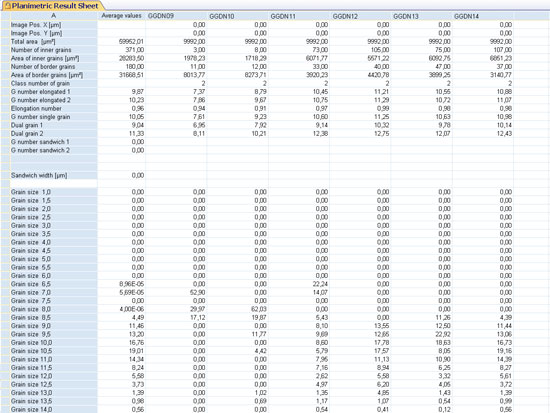

Report/OutputReport/Output: Spreadsheet (G number :elongated, single grain, sandwich, elongation number, dual grain, percent of grains / class), Chart (Grain size frequency distribution), Image with overlay (Detected grain bounderies) Report/OutputReport/Output: Spreadsheet (G number :elongated, single grain, sandwich, elongation number, dual grain, percent of grains / class), Chart (Grain size frequency distribution), Image with overlay (Detected grain bounderies)

|

|

|

|

Settings

The settings are divided into three easy-to-use parts: general settings, report settings and the separator definition, making specific settings easy accessible. The general settings provide the basic parameters, such as measurement area or the sandwich threshold. In report settings the user is prompted to enter header data, which enables the automatic completion of reports to be compliant with predefined standards. It can also arrange the spreadsheet in accordance with individual specifications. The separator definition dialogue box enables the grain boundary detection settings to be adjusted and tested, as required. |

|

Execution

Once all of the settings have been defined, the measurement can be executed with a simple click on the ‘Detect Grains’ icon. A series of images can also be analysed automatically, using the previously defined settings. Each of the images is analysed individually and the results are subsequently accumulated in the last step of the workflow. Finally, a report detailing the results is created automatically.s. |

|

Results – compliant to DIN 50601, JIS G 0552, ASTM E 112

For each image, a grain size frequency distribution diagram is generated. Furthermore, a detailed measurement report for each image will be entered into a planimetric sheet, followed by an in-depth analysis of the different areas of the individually detected grains. Providing additional flexibility, the user is able to summarise and accumulate the results onto a single sheet.

|

|

| |